CD1/MD1電動葫蘆減速器怎么加油?

CD1/MD1電動葫蘆減速器怎么加油?以CD1/MD1鋼絲繩電動葫蘆為例,自上部注孔注入起升機構減速器,齒輪油HL-10或機械油HJ-50,三個月一次。0.25噸電動葫蘆加0.2升,0.5噸電動葫蘆加0.75升,1噸電動葫蘆加0.75升,2噸電動葫蘆加1.5升,3噸電動葫蘆加1.7升,5噸電動葫蘆加2.5升,10噸電動葫蘆加3升,16噸電動葫蘆加3升。

CD1/MD1 electric hoist reducer how to oil? Take CD1/MD1 wire rope electric hoist as an example. Lift mechanism reducer, gear oil hl-10 or mechanical oil hj-50 are injected into the upper injection hole once every three months. 0.25 ton electric hoist plus 0.2 l, 0.5 ton electric hoist plus 0.75 l, 1 ton electric hoist plus 0.75 l, 2 ton electric hoist plus 1.5 l, 3 ton electric hoist plus 1.7 l, 5 ton electric hoist plus 2.5 l, 10 ton electric hoist plus 3 l, 16 ton electric hoist plus 3 l.

CD1/MD1電動葫蘆減速器為什么加油?(CD1/MD1 electric hoist reducer why refueling?)

減速箱或軸承需要定期更換潤滑油,如果沒有按要求潤滑,減速器不僅會產生過高的噪聲,還會過度磨損或損壞齒輪及軸承,嚴重的會導致物料墜落情況。在設備操作時有人認為減速機暫時不加或隨便加點潤滑油,照樣能運轉,不會發生嚴重故障,這種思想是錯誤的。操作員初次使用沒有閱讀說明書,沒有按要求給減速機內加注潤滑油,在使用過程中產生很大的響聲,并出現物料墜落,經后期檢查打開減速箱,發現齒輪磨損過度報廢,減速軸承損壞,出現異響。這種情況需返廠拆卸檢修或更換,解決故障,消除噪音。

Gearbox or bearing needs to replace the lubricating oil regularly. If not lubricated as required, the reducer will not only produce excessive noise, but also excessive wear or damage to the gear and bearing, serious will lead to material fall. In the operation of equipment, some people think that the reducer can still operate without adding lubricating oil temporarily or casually, without serious failure. This idea is wrong. In the first use, the operator did not read the manual and did not add lubricating oil to the reducer as required. During the use, there was a big noise and falling of materials. After opening the reducer box after the later inspection, it was found that the gear was excessively worn out, the reducer bearing was damaged and abnormal sound occurred. This kind of circumstance needs to return the factory to dismantle overhaul or change, solve breakdown, eliminate noise.

CD1/MD1電動葫蘆減速器為什么漏油?(CD1/MD1 electric hoist reducer why oil leakage?)

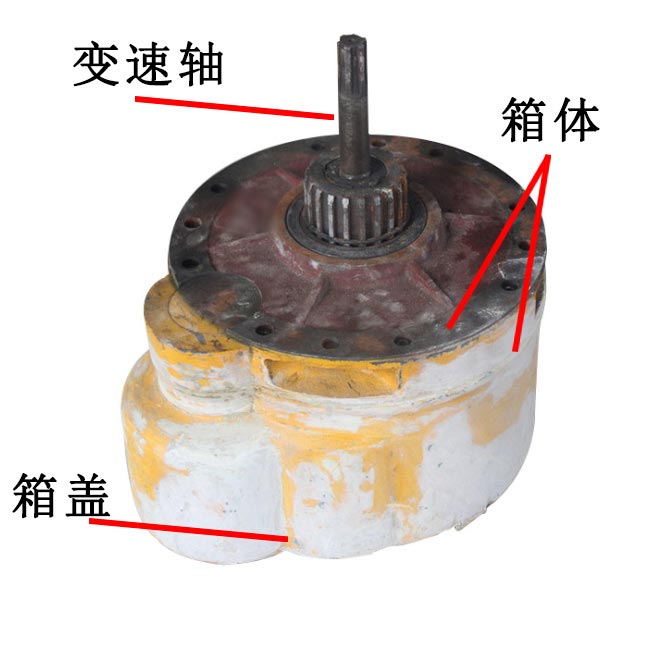

1、密封失效;2、箱體變形;3、剖分面不平;4、連接螺栓松動;5、此外在設備檢修時,由于結合面上污物清除不徹底,或密封膠選用不當、密封件方向裝反、不及時更換密封件等也會引起漏油;6、加油量過多:減速機在運轉過程中,油池被攪動得很厲害,潤滑油在機內到處飛濺,如果加油量過多,使大量潤滑油積聚在軸封、結合面等處,導致泄漏;7、減速器內外的壓力差較大:減速器運行轉動過程中,運動摩擦發熱以及受外界環境溫度的影響,使減速器溫度升的過高,如果沒有透氣孔等出氣地方,則起重機機內壓力逐漸增加,機內溫度也會越高,與外界的壓力差便會越大,潤滑油在壓差作用下,從縫隙處漏出。

1. Seal failure; 2. Box deformation; 3. Uneven split surface; 4. Loose connection bolts; 5, in addition, in the maintenance of equipment, due to the combination of surface dirt is not completely removed, or improper selection of sealant, sealing parts installed in the wrong direction, not timely replacement of sealing parts will also cause oil leakage; 6, too much oil: the reducer in the process of operation, the oil tank is stirred very badly, the oil in the aircraft everywhere splash, if too much oil, so that a large amount of lubricating oil accumulation in the shaft seal, joint surface, resulting in leakage; Pressure difference inside and outside is bigger: 7, reducer reducer running in the process of turning movement friction heat and influenced by the environment temperature, reduce the temperature rise is too high, if there is no air holes vent place, such as increasing pressure on the crane machines, machine temperature will be higher, the greater the pressure difference with the outside world will, lubricating oil under the action of pressure difference, the leakage from the gap.

電動葫蘆減速器漏油處理措施:1、更換密封件;2、檢修箱體剖分面,變形嚴重則更換;3、剖分面鏟平;4、清理回油槽,緊固螺栓。

Electric hoist reducer leakage treatment measures: 1, replace the seal; 2. Check the box body section surface, and replace it if the deformation is serious; 3. Section plane leveling; 4. Clean up the oil groove and tighten the bolts.

CD1/MD1電動葫蘆減速器運行中如發現齒輪轉動噪聲太大,需要檢查是否存在齒輪齒面有磕碰傷痕,齒輪加工精度低,齒輪副裝配精度低;缺油、潤滑不良;齒輪、軸承等磨損嚴重;齒輪箱內清潔度是否合格等。如果發現是上述原因造成的那么采取相應的措施即可。

In the operation of CD1/MD1 electric hoist reducer, if it is found that the gear rotation noise is too big, it is necessary to check whether there is bump scar on the gear tooth surface, the gear processing accuracy is low, and the gear assembly accuracy is low; Lack of oil and poor lubrication; Serious wear of gears and bearings; Cleanliness of gearbox, etc. If it is found to be caused by the above reasons, then the corresponding measures can be taken.

友情提示 (Helpful hints)

嚴禁超載、斜拉、CD1/MD1電動葫蘆作業時下面嚴禁站人或作業,使用前請加潤滑油。設備隨機附有控制箱、限位器接線說明書,設備安裝前請認真閱讀。

Overload, pull, CD1/MD1 electric hoist operation is strictly prohibited to stand below or operation, please add oil before use. The equipment is attached with the wiring instruction of control box and limit device. Please read it carefully before installation.